Trey & Pedro: How long have you been teaching here?

Mr. Stevenson: I started teaching as a substitute teacher in 2011 while taking courses to reinstate my math teaching license. When Mr. Meagher discovered that I was an electrical engineer, he asked me to consider teaching full time in robotics. I had to take the VTEL test to prove I could read and write English, then a written and practical test to become certified in electronics, then three courses to meet the city requirements for new teachers. I began full time teaching relay ladder programming to sophomores using LogixPro in the fall of 2012. I knew the schematic diagram format and several programming languages but the relay ladder diagram format and constraints of the ladder diagram programming were new to me and I learned right along with my students. In the following years I had to take and pay for seven more courses to become certified in Vocational Teaching. I became fully certified professionally in 2017. So this makes this my seventh year full-time teaching.

Do you like teaching here?

After having done substitute teaching at other schools in the city, I find WTHS the best high school in the city. The students are generally better behaved, more respectful, and more focused because of the less restrictive shop environment. I love my students and I want them to be prepared for a productive future. I enjoy seeing my students grow physically and mature in attitude as they go from freshmen to seniors. I am able to spend more time with my students than I was able to spend with my sons when they were that age.

Why did you choose this career?

Engineering was natural for me. I began at an early age with crystal radios, the early transistors in the 1950s which my father brought home, tube radios and amplifiers. I was in the college prep course at Burncoat Junior High. I did well in math and sciences. I became a licensed amateur radio operator and built my own transmitter communicating by Morse code with amateur radio operators throughout the world, collecting QSL cards. When my high school counselor, Mr. Steadt, suggested electrical engineering, I agreed. I applied to WPI and Northeastern University but chose Northeastern University for two reasons; the co-op program and I would be living away from home but close enough to be home in an hour on the B&W (Boston & Worcester) bus line. I was able to come home on weekends to teach a crafts class and electronics class at the Worcester Boys Club.

How long have you been in the industry?

I started at Techni-Rite electronics in April of 1970. I missed my first day of work because of a snowstorm on Easter Sunday and I had just taken off my snow tires the day before so I was unable to get out of my driveway. What a way to start a new job! I am still working in engineering

What is it like in the Robotics industry?

I had the good fortune to be employed initially at Techni-Rite electronics which at that time manufactured heated stylus strip chart recorders in single to four channels for EKG (or ECG) heart monitoring. They also produced a line of 1, 2, 4, and 8 channel recorders used in laboratories and commercial applications for recording many parameters such as temperature, pressure, power, speed, position, etc. Each of these parameters required an analog interface called a signal conditioner to convert the parameter to the voltage type and range required by the recorder. I made modifications to existing signal conditioners as needed by customer requirements and designed signal conditioners for new applications. One was a phase-sensitive demodulator for the Canadian Navy. We designed and manufactured recorders for aircraft and military applications including a 60 channel event recorder for McNamara’s fence in the Vietnam War.

Over 30 years, the founder of Techni-Rite and vice president of engineering, Leo Valenti, gave me many tasks such as applications manager to work with customers who needed special variations of our recorders; traveling with our salesmen and distributors to support them technically; troubleshoot problems on the manufacturing production line; technical support for marketing; quality control manager at our West Instruments temperature control manufacturing plant in Chicago, Illinois; training sales staff internationally; designing new temperature controllers for the West and LFE (originally Laboratory For electronics in Waltham Massachusetts) temperature controllers and digital panel meters, and production line manager for West Instruments temperature controllers. Leo knew that I would execute faithfully any task he would give me.

Today, I am keeping active in engineering design working part-time for Leo Valenti in his company VSquare/R on energy control products. This has given me the opportunity to have some of my students work on parts of the projects and even employ some students part-time as my technicians.

Recently I asked Leo Valenti, now 95 years old, “Forty years ago, why did you hire me over all the other engineering applicants?” His answer was quick, immediate and short, “motivation”. He said when hiring engineers, he looked for motivation first and competency second. A motivated engineer will find a way to solve problems, even acquiring and developing new competencies whereas an engineer with all the competencies and low motivation may not finish solving the problem on time or at all. I had one such engineer work for me who was like that. He was laid off without having finished the project. I was then tasked with the project and completed it with new technology which I had to learn. This became the updated Wellogger using the Xilinx FPGA.

Why is the career so important and interesting for you?

This career is interesting and fulfilling on many levels. It has given me the opportunity to develop unique solutions to analog and digital circuits, design complete products including assigning model numbers, interface with customers both face to face and on the telephone, publish technical articles, teach and train customers, sales staff, and technicians, travel internationally and experience different cultures, experience new and different foods such as abalone, calamari, oysters on the half shell, Italian, Indian, authentic Chinese and authentic Greek food, calves brains oreganata, alligator, rattlesnake, turtle soup, and prairie oysters on the company expense account.

What have you worked on in your industry?

I have run the full range of electro mechanical systems, strip chart recorders, medical products, analog circuit design with transistors and op-amps (operational amplifiers), d.c. power supplies, temperature controllers, PLCs, designed microprocessor systems and digital logic systems with Xilinx FPGAs (Field Programmable Gate Arrays),written printer drivers and demo programs for the IBM PC in DOS, and programmed in several languages, BASIC, Forth, PL65, Fortran, C, VHDL, and assembly language for the Motorola, Intel and Rockwell microprocessors, D.C motors, a.c. synchronous, and stepper motors.

Where have you worked?

While a student at Northeastern University, I had a co-op job as a technician for four years at the MIT Instrumentation Laboratory in Cambridge. I graduated from Northeastern University in 1967 with a Bachelor’s degree in Electrical Engineering. Because of my good experiences in teaching an electronics class at the Worcester Boys Club, I decided to teach and started with teaching math at Burncoat Senior High school which lasted from 1967 to 1970. I liked teaching but the lack of respect and low pay convinced me that I would be better off in engineering. It was then that I was hired at Tehni-Rite electronics in Olneyville, Rhode Island. I commuted from Worcester for two years until I was run off the road and nearly had a head on collision on Route 146 which was only two lanes at that time with dirt shoulders. I moved to an apartment in Providence. I worked for the company for 30 years as it was acquired by Gulton Industries, then two holding companies in succession, Danaher Corporation and Mark IV. The plant closed in 1999 and the product lines were dispersed to other businesses owned by mark IV. I then went to work for Atlantek in Wakefield Rhode Island. Atlantek was s spin off of Gulton, manufacturing thermal printers and founded by former Gulton engineers. Atlantek bought the Wellogger printer line from Mark IV because it did not fit with their other product lines. I managed the production line for the Wellogger and worked on the design of new thermal printers. Atlantek had a downturn in business and I was laid off a year later.

While taking some time off visiting my wife’s parents at a condo in Florida, my wife saw an ad for espresso machine distributorships. Well, we liked coffee, so we bought into it and quickly found out that the company was nor very reputable and provided little support. We then went to the parent company and manufacturer, Comobar 2000 and worked directly with them. I developed a rental business for espresso and cappuccino machines in all the New England states. My wife and I promoted or products at trade shows in New England This required much driving, as much as 10 to 11 hours a day. I acted as engineering consultant for Comobar on their new coffee machine to compete with Keurig. My espresso business was just breaking even in 2008 when the economy took a downturn with the policies of the new president. My restaurant customers began losing business with some going bankrupt and keeping my machines. The price of gasoline had risen to around $4 per gallon and my travel costs skyrocketed. By 2012, the business was nearly dead and went bankrupt.

I then advertised for math tutoring and secured several students whom I tutored from sophomore year until high school graduation. I also tutored two home school students in math and physics for two years.

Being laid off twice and being president of my own failed business has brought me to the happy circumstances of teaching at WTHS where I can use my technical knowledge. I have the best of both worlds by enjoying my students who keep me young in spirit if not in body, and working in engineering for VSquare/R for a very energetic and forward-thinking engineer in his 90s.

Has the industry been good for your mental and physical health?

The company I worked for presented no problems for physical health because it was in an office and lab environment with some occasional travel. The stress level was not high because I had a good boss. Mental health was great for many reasons. I was always challenged with solving new problems, learning new products, and supported with the resources to meet the challenges. I was also mostly insulated from the company politics. Leo Valenti was very good at defusing heated meetings with sales, marketing, production and quality control when things had wrong and everyone was looking for someone to blame. Leo would take responsibility for his department and just say, “We screwed up. Now where do we go from here?”

Advice for going into the field of engineering?

Prospective engineering students need to do well in math and sciences, be well-motivated to solve problems and value the reward of solving a problem above the monetary rewards. Students should be engaged in activities and hobbies that are in line with their selected engineering discipline.

When do you plan on retiring?

Retire? What is that? My former boss, Leo Valenti still has not retired. Seriously, I like working with Mr. Meagher and Mr. Leboeuf. We make a good team and complement each other’s talents and experiences. As we age, my wife’s health and my health are deteriorating. I intend to teach for as long as three conditions are met; my health holds up, my wife’s health holds up and I have students who are interested and willing to learn, especially those looking for an engineering career.

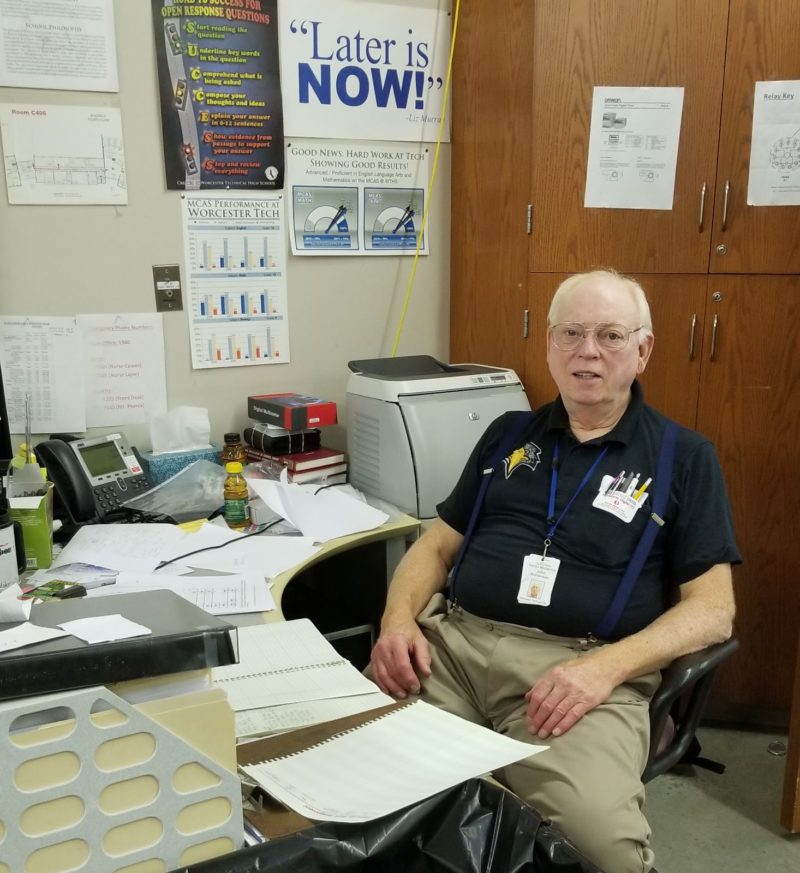

Mr.Stevenson can be found in C406